-

Thermal Camera Core

-

Thermal Security Camera

-

Drone Thermal Camera

-

Plug-in Thermal Camera

-

Cooled Infrared Detectors

-

Cooled Camera Modules

-

Optical Gas Imaging

-

Infrared Thermal Camera Module

-

High Resolution Thermal Camera Module

-

Thermal Camera For Fever Detection

-

Vehicle Mounted Thermal Camera

-

Integrated Dewar Cooler Assembly

-

Uncooled Infrared Detectors

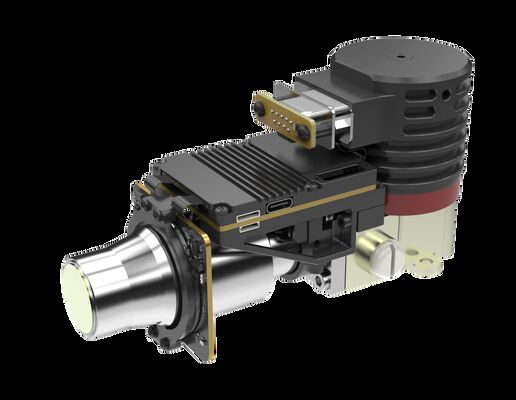

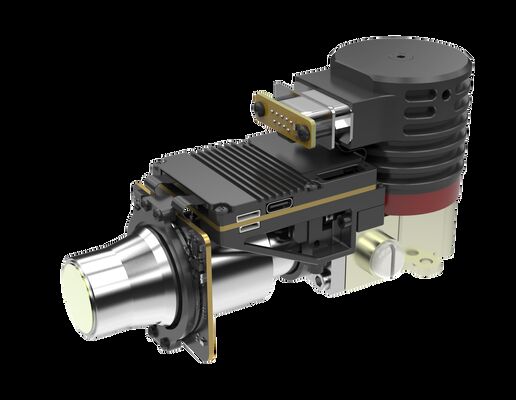

MWIR 320x256/30µm Optical Gas Imaging Camera Core for Handheld Thermal Imager

| Spectral Range | 3.8±0.1~4.1±0.1μm | Style | Cooled Infrared Module |

|---|---|---|---|

| Weight | ≤680g | Size | 142mm×58.5mm×80mm |

| Resolution | 320x256/30μm | NETD | 20mK (F3) |

| Highlight | 23mm Lens MWIR Camera,Gas Leak Visualizing MWIR Camera,ISO9001 Optical Gas Imaging Camera |

||

The LFM330Z5 is a cooled infrared camera module specifically engineered for temperature measurement through flames in high-temperature industrial environments. It integrates a 320x256/30µm cooled MWIR infrared detector to visualize high-temperature targets in flame-intensive conditions where traditional detection methods fail.

- Clear gas imaging with high sensitivity optical configuration

- High reliability for demanding industrial applications

- Easy integration with support for various interfaces and RAW/YUV image output

- Wide application scenarios suitable for handheld, mobile, or fixed platforms

| Module Model | LFM330Z5 |

|---|---|

| Resolution | 320*256 |

| Pixel Size | 30μm |

| Spectral Response | 3.8±0.1μm~4.1±0.1μm |

| Typical NETD | 20mK (F3) |

| Frame Rate | 30Hz/60Hz |

| Digital Video Interfaces | Standard: DVP/LVDS/USB2.0 Optional: Cameralink/USB3.0/GigE/SDI/MIPI/Single-mode fiber/Multi-mode fiber |

| Communication Interfaces | Standard: USB2.0/LV-TTL Optional: RS422/CAN/USB3.0/GigE |

| Cooling Time (23℃) | ≤8min@12V |

| Stable Power Consumption (23℃) | ≤10W |

| Dimensions | 142*58.5*80 mm |

| Weight | ≤680 g |

| Operating Temperature | -40℃~+71℃ |

| Focal Length Options | 23mm/55mm |

- Metallurgical operations including steelmaking, aluminum smelting, and copper refining

- Petrochemical plants operating fired heaters, reformers, crackers, and incinerators

- Power plants with coal-fired, gas-fired, and biomass boilers

- Time-saving & Efficient: Supports large-scale real-time detection and rapid leak location without interrupting production

- Long Range Detection: Non-contact testing from safe distances without additional radiation sources

- Easy to Analyze: Intuitive imaging with instant storage and convenient analysis capabilities

- Multi-function Inspection: Detects various gases with excellent remote temperature measurement functionality

Optical gas imaging is an infrared technology that visualizes invisible industrial gases. When gases absorb infrared radiation at specific wavelengths, they create a radiation difference between the gas and background. The gas leak detection infrared detector with built-in narrowband filter receives only the infrared band near the gas absorption peak, converting the radiation difference into visible infrared images.