-

Thermal Camera Core

-

Thermal Security Camera

-

Drone Thermal Camera

-

Plug-in Thermal Camera

-

Cooled Infrared Detectors

-

Cooled Camera Modules

-

Optical Gas Imaging

-

Infrared Thermal Camera Module

-

High Resolution Thermal Camera Module

-

Thermal Camera For Fever Detection

-

Vehicle Mounted Thermal Camera

-

Integrated Dewar Cooler Assembly

-

Uncooled Infrared Detectors

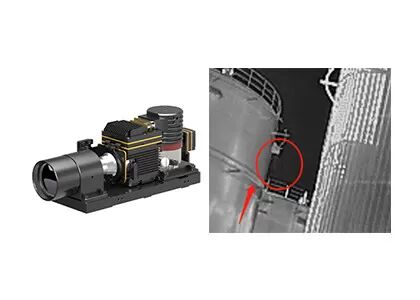

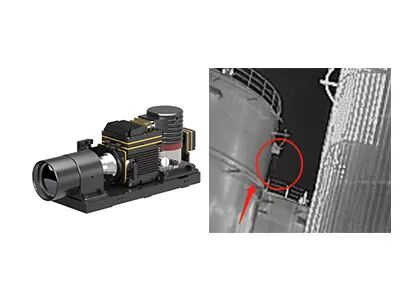

MWIR Cooled Infrared Camera Module for Non Contact Gas Leakage Detection

| Resolution | 320x256 / 30μm | Spectral Range | 3.2±0.1~3.5±0.1μm |

|---|---|---|---|

| NETD | ≤15mK | Frame Rate | 30Hz |

| Product Size | 155x67x80mm | Product Weight | ≤900g |

| Highlight | 15mK Infrared Camera Module,900g Infrared Camera Module |

||

320x256 / 30μm Cooled Infrared Camera Module for Non-contact Gas Leakage Detection

GAS330 is a cooled infrared thermal imaging module specially designed for gas leakage detection. It can automatically detect gas leaks of many industrial gases in a few seconds accurately and safely without the need of shutting down any systems.

GAS330 infrared gas leak detection camera uses 320x256 / 30μm cooled MWIR infrared detector. It has an advantages of non-contact measurement in dangerous areas or areas that are difficult to access, so as to ensure the safety of inspection personnel.

By using this infrared thermal imaging technology in the petrochemical industry, the safety production, environmental protection supervision and cost saving can be ensured.

- Resolution: 320x256

- Pixel Pitch: 30µm

- NETD≤15mK, High Sensitivity

- Spectral Response: 3.2µm±0.1µm~3.5µm±0.1µm

- Wavelength Customizable Based on Different Requirements

- Integrate with DVP/CameraLink Interface Easily

| Model | GAS330 |

| IR Detector Performance | |

| Resolution | 320x256 |

| Pixel Pitch | 30μm |

| Cryocooler | RS058 |

| Spectral Range | 3.2μm±0.1μm~3.5μm±0.1μm MW |

| Cooling Time (20°C) | ≤8min |

| NETD (20°C) | ≤15mK |

| Image Processing | |

| Frame Rate | 30Hz |

| Dimming Mode | Linear/Histogram/Mixed |

| Digital Zoom | ×1/×2/×4 |

| Image Direction | Horizontally/Vertically/Diagonally Flip |

| Image Algorithm | NUC/AGC/IDE |

| Electrical Specification | |

| Standard External Interface | J30JZ 25pin |

| Analog Video | PAL |

| Digital Video | 16bit RAW/YUV: 16bit DVP/Cameralink Output |

| External Sync | Frame External Sync: RS422 Level |

| Communication | RS422, 115200bps |

| Power Supply | 20~28VDC |

| Stable Power Consumption | 12W |

| Dimension (mm) | 155×67×80 |

| Weight | ≤900g |

| Operation Temperature | -40°C ~ +60°C |

| Vibration Magnitude | Vibration: GJB Vehicle-mounted High Speed Transport Shock: Half-sine Wave, 40g 11 ms, 3 Axis 6 Direction 3 Times Each |

| Optical Lens | |

| Optional Lens | Fixed Zoom: 23mm/F1.5; 55mm/F1.5 |

The GAS330 gas leak detection thermal imaging camera is used for visiualizing the invisible VOCs (volatile organic compounds) and detecting gas leakage such as: Methane, Ethane, Propane, Butane, Pentane, Hexane, Heptane, Octane, Ethylene, Propylene, Isoprene, Methanol, Ethanol, Butanone, Benzene, Toluene, Xylene, Ethylbenzene etc.

SensorMicro was founded with a simple but powerful belief: Innovation should serve real-world needs.

SensorMicro exists to empower people and systems to see beyond the surface—into the patterns, the problems, and the possibilities that lie beneath.

By turning invisible heat into visible truth, we help industries make smarter decisions, protect what matters most, and navigate complexity with clarity.

Heeding to our insistence on being self-made and customer-first has become a sure recipe for SensorMicro's momentum. As our business spans much of the globe, we've charged ahead on all fronts—from security, firefighting, industrial inspection, medical care, and machine vision, to environmental monitoring and key aspects of carbon neutrality—helping partners unlock the full potential of intelligent infrared sensing, and connecting the dots of life.

We are more than an infrared technology company. We are a community of people committed to building a sustainable, ethical, and human-centered future. Every pixel of innovation we create is a promise — a promise to protect, to empower, and to serve.

1.What is infrared thermography?

Thermography is a new and effective technology of non-invasive diagnostic method based on object surface temperature detection. The infrared (IR) radiation emitted from an object is recorded and visualized in the form of a temperature distribution map.

2. What can the infrared thermography be used for?

The infrared thermal image can be used to perform home inspections, determine structural defects, electrical faults, mechanical faults, physiological changes in people & animals and much more.

3.What are the advantages of infrared thermography?

For the non-destructive test, it is simple to test and quick to response without damage, which results in saving costs, increasing work efficiency, reducing manpower and equipment depreciation.

For the medical thermography, it is very efficient to find the hidden problems in human body, 100% safe without radiation and pain, which is an ideal tool for early health screening.