All Products

-

Thermal Camera Core

-

Thermal Security Camera

-

Drone Thermal Camera

-

Plug-in Thermal Camera

-

Cooled Infrared Detectors

-

Cooled Camera Modules

-

Optical Gas Imaging

-

Infrared Thermal Camera Module

-

High Resolution Thermal Camera Module

-

Thermal Camera For Fever Detection

-

Vehicle Mounted Thermal Camera

-

Integrated Dewar Cooler Assembly

-

Uncooled Infrared Detectors

Contact Person :

Wendy Wang

Phone Number :

+86 27 50185150

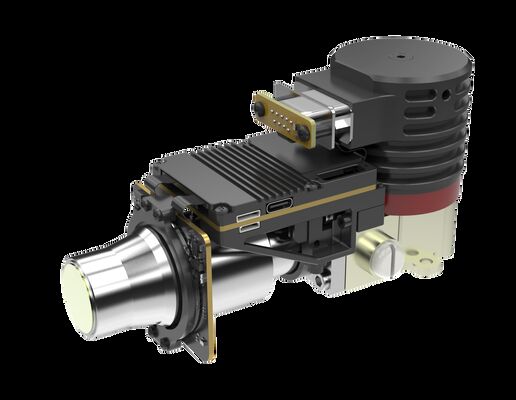

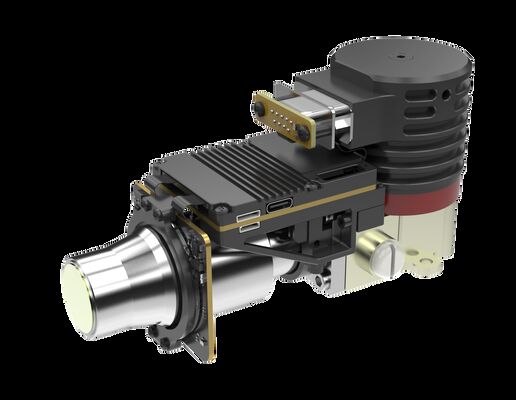

23mm Lens MWIR Optical Gas Imaging Cooled Infrared Module with 320x256/30μm for Industrial Applications

Product Details

| Size | 142mm×58.5mm×80mm | Style | Cooled Infrared Module |

|---|---|---|---|

| Optional Lens | 23mm/55mm | Resolution | 320x256/30μm |

| NETD | 20mK (F3) | Spectral Range | 3.8±0.1~4.1±0.1μm |

| Highlight | MWIR Cooled Infrared Module,23mm Lens Cooled Infrared Module |

||

Product Description

23mm Lens MWIR Optical Gas Imaging Cooled Infrared Module

Advanced Thermal Imaging for Metallurgy and Petrochemical Applications

In metallurgical and petrochemical industrial environments, equipment such as furnaces, furnace walls, and heating furnaces operate in high-temperature combustion conditions with significant flame interference. Traditional detection methods struggle to provide effective observation of internal structures or surface conditions.

The LFM330Z5 cooled infrared camera module is specifically engineered for temperature measurement through flames. Integrating a 320×256 / 30µm cooled MWIR infrared detector, this thermal imaging module visualizes high-temperature targets in flame-intensive environments with exceptional flame penetration capabilities.

SensorMicro provides comprehensive infrared thermal imaging integration solutions, professional technical support, and complete after-sales services for gas leak detection applications. Camera manufacturers can efficiently integrate this infrared module to design customized gas leak detection systems.

Key Features

- Clear gas imaging with high sensitivity optical configuration

- High reliability for demanding industrial environments

- Easy integration supporting multiple interfaces and RAW/YUV image output

- Versatile application scenarios suitable for handheld, mobile, or fixed platforms

Technical Specifications

| Module Model | LFM330Z5 |

|---|---|

| Resolution | 320×256 |

| Pixel Size | 30μm |

| Spectral Response | 3.8±0.1μm~4.1±0.1μm |

| Typical NETD | 20mK (F3) |

| Frame Rate | 30Hz/60Hz |

| Digital Video | Standard: DVP/LVDS/USB2.0 Optional: Cameralink/USB3.0/GigE/SDI/MIPI/Single-mode fiber/Multi-mode fiber |

| Communication | Standard: USB2.0/LV-TTL Optional: RS422/CAN/USB3.0/GigE |

| Cooling Time (23℃) | ≤8min@12V |

| Stable Power Consumption (23℃) | ≤10W |

| Size (mm) | 142×58.5×80 |

| Weight (g) | ≤680 |

| Working Temperature | -40℃~+71℃ |

| Focal Length | 23mm/55mm |

Industrial Applications

The LFM330Z5 cooled thermal imaging camera core enables temperature measurement through flames in critical industrial processes:

- Metallurgical operations including steelmaking, aluminum smelting, and copper refining involving high-temperature furnaces, converters, and ladles

- Petrochemical plants operating large-scale fired heaters, reformers, crackers, and incinerators

- Coal-fired, gas-fired, and biomass power plants with intense flame combustion systems

Our Product Line

Frequently Asked Questions

What are the applications of optical gas imaging infrared camera core?

Real-time temperature profiling of molten metal: Penetrating furnace flames to measure temperature distribution of steel ladles, blast furnace tuyeres, or aluminum smelting pots, preventing overheating or uneven heating that causes product defects.

Furnace internal condition monitoring: Visualizing the integrity of furnace linings through flames—detecting cracks, erosion, or hot spots early to prevent equipment failure and production downtime.

Continuous casting process control: Measuring strand surface and mold interface temperatures through protective flame shrouds to optimize cooling and ensure uniform solidification.

Fired heater tube wall temperature monitoring: Penetrating flame envelopes to measure heat exchanger tube temperatures, preventing leaks of flammable/explosive media.

Catalytic cracking unit monitoring: Visualizing temperature distribution of regenerator beds through combustion flames to ensure optimal catalyst regeneration efficiency.

Waste incinerator emission and combustion control: Measuring incineration chamber temperatures through flames to optimize air-fuel ratios and ensure regulatory compliance.

Furnace internal condition monitoring: Visualizing the integrity of furnace linings through flames—detecting cracks, erosion, or hot spots early to prevent equipment failure and production downtime.

Continuous casting process control: Measuring strand surface and mold interface temperatures through protective flame shrouds to optimize cooling and ensure uniform solidification.

Fired heater tube wall temperature monitoring: Penetrating flame envelopes to measure heat exchanger tube temperatures, preventing leaks of flammable/explosive media.

Catalytic cracking unit monitoring: Visualizing temperature distribution of regenerator beds through combustion flames to ensure optimal catalyst regeneration efficiency.

Waste incinerator emission and combustion control: Measuring incineration chamber temperatures through flames to optimize air-fuel ratios and ensure regulatory compliance.

Recommended Products