-

Thermal Camera Core

-

Thermal Security Camera

-

Drone Thermal Camera

-

Plug-in Thermal Camera

-

Cooled Infrared Detectors

-

Cooled Camera Modules

-

Optical Gas Imaging

-

Infrared Thermal Camera Module

-

High Resolution Thermal Camera Module

-

Thermal Camera For Fever Detection

-

Vehicle Mounted Thermal Camera

-

Integrated Dewar Cooler Assembly

-

Uncooled Infrared Detectors

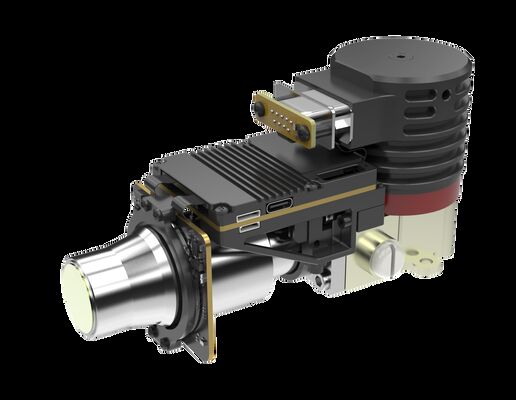

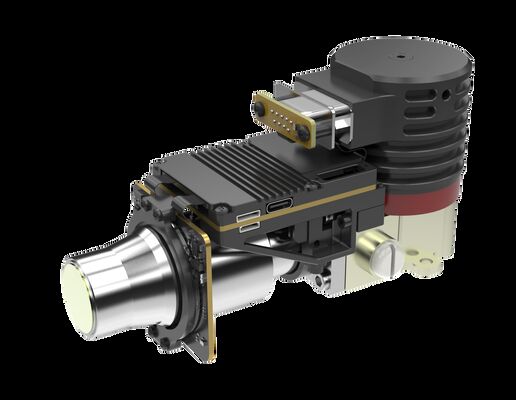

55mm Lens Optical Gas Imaging Camera Core with 320x256 Resolution for Flame Penetration in High-Temperature Environments

| Optional Lens | 23mm/55mm | Style | Cooled Infrared Core |

|---|---|---|---|

| Resolution | 320x256/30μm | NETD | 20mK (F3) |

| Spectral Range | 3.8±0.1~4.1±0.1μm | Size | 142mm×58.5mm×80mm |

| Highlight | VOCs Gas Imaging Module,55mm Lens Gas Imaging Module |

||

The LFM330Z5 thermal camera core is specifically engineered for high-temperature observation applications in flame environments. It delivers exceptional flame penetration capabilities, enabling accurate imaging and monitoring of high-temperature target surfaces such as furnaces and furnace walls.

- Clear gas imaging with high sensitivity optical configuration

- High reliability for demanding industrial environments

- Easy integration with support for various interfaces and RAW/YUV image output

- Wide application scenarios suitable for handheld, mobile, or fixed platforms

| Module model | LFM330Z5 |

| Resolution | 320*256 |

| Pixel size | 30μm |

| Spectral response | 3.8±0.1μm~4.1±0.1μm |

| Typical NETD | 20mK (F3) |

| Frame rate | 30Hz/60Hz |

| Digital video | Standard: DVP/LVDS/USB2.0 Optional: Cameralink/USB3.0/GigE/SDI/MIPI/Single-mode fiber/Multi-mode fiber |

| Communication | Standard: USB2.0/LV-TTL Optional: RS422/CAN/USB3.0/GigE |

| Cooling time (23 ℃) | ≤8min@12V |

| Stable power consumption (23 ℃) | ≤10W |

| Size (mm) | 142*58.5*80 |

| Weight (g) | ≤680 |

| Working temperature | -40℃~+71℃ |

| Focal length | 23mm/55mm |

The LFM330Z5 cooled thermal imaging camera core enables temperature measurement through flames in various industrial processes:

- Metallurgical operations including steelmaking, aluminum smelting, and copper refining

- Petrochemical plants operating large-scale fired heaters, reformers, crackers, and incinerators

- Coal-fired, gas-fired, and biomass power plants relying on boilers with intense flame combustion

Strong R&D Capabilities: SensorMicro is one of China's earliest companies researching antimonide-based Type-II superlattice (T2SL) cooled infrared detectors, with proven capabilities in R&D and manufacturing of high-end advanced devices.

Leading Technological Achievements: Leads the development trend of SWaP³ technology in the industry, with advantages in large-format array, small pixel, high-temperature operation, miniaturization, high performance, and low power consumption.

Complete Supply Chain: From cutting-edge chip design and precise cooler manufacturing to high vacuum packaging processes, ensuring stable supply chain, reliable quality, and significant cost advantages.

What are the applications of optical gas imaging infrared camera core?

- Real-time temperature profiling of molten metal in steel ladles, blast furnace tuyeres, or aluminum smelting pots

- Furnace internal condition monitoring for detecting cracks, erosion, or hot spots

- Continuous casting process control for optimizing cooling water flow

- Fired heater tube wall temperature monitoring to prevent leaks of flammable/explosive media

- Catalytic cracking unit (CCU) monitoring for optimal catalyst regeneration efficiency

- Waste incinerator emission and combustion control for compliance with emission standards