All Products

-

Thermal Camera Core

-

Thermal Security Camera

-

Drone Thermal Camera

-

Plug-in Thermal Camera

-

Cooled Infrared Detectors

-

Cooled Camera Modules

-

Optical Gas Imaging

-

Infrared Thermal Camera Module

-

High Resolution Thermal Camera Module

-

Thermal Camera For Fever Detection

-

Vehicle Mounted Thermal Camera

-

Integrated Dewar Cooler Assembly

-

Uncooled Infrared Detectors

Contact Person :

Wendy Wang

Phone Number :

+86 27 50185150

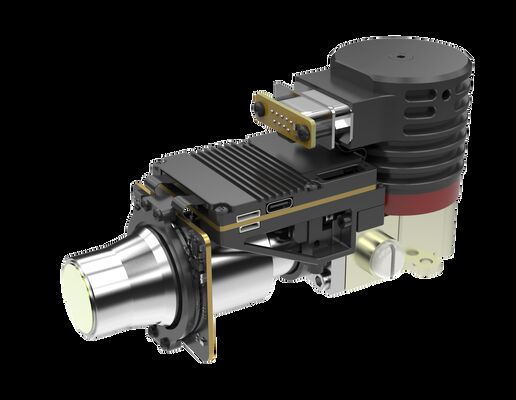

Cooled 320×256/30μm OGI Infrared Camera Core for Measurement through Flames with 23mm/55mm Lens

Product Details

| Spectral Range | 3.8±0.1~4.1±0.1μm | Function | Measurement Through Flames |

|---|---|---|---|

| NETD | 20mK (F3) | Frame Rate | 30Hz/60Hz |

| Detector Resolution | 320x256 | Pixel Size | 30μm |

| Highlight | Fixed Zoom Lens OGI Camera,RS422 Communication OGI Camera |

||

Product Description

Cooled 320*256/30μm OGI Optical Gas Imaging Infrared Camera Core with 23mm/55mm Lens

Product Overview

The LFM330Z5 thermal camera core is specifically engineered for high-temperature observation applications in flame environments. Designed for industrial sites such as metallurgy and petrochemical plants, this cooled optical gas imaging infrared camera core delivers exceptional flame penetration capabilities, enabling accurate imaging and monitoring of high-temperature surfaces including furnaces, furnace walls, and heating equipment.

Key Features

Clear gas imaging with high sensitivity optical configuration

High reliability for demanding industrial environments

Easy integration supporting various interfaces and RAW/YUV image output

Versatile application scenarios suitable for handheld, mobile, or fixed platforms

Technical Specifications

| Module Model | LFM330Z5 |

|---|---|

| Resolution | 320*256 |

| Pixel Size | 30μm |

| Spectral Response | 3.8±0.1μm~4.1±0.1μm |

| Typical NETD | 20mK (F3) |

| Frame Rate | 30Hz/60Hz |

| Digital Video | Standard: DVP/LVDS/USB2.0 Optional: Cameralink/USB3.0/GigE/SDI/MIPI/Single-mode fiber/Multi-mode fiber |

| Communication | Standard: USB2.0/LV-TTL Optional: RS422/CAN/USB3.0/GigE |

| Cooling Time (23℃) | ≤8min@12V |

| Stable Power Consumption (23℃) | ≤10W |

| Size | 142*58.5*80 mm |

| Weight | ≤680 g |

| Working Temperature | -40℃~+71℃ |

| Focal Length | 23mm/55mm |

Industrial Applications

Metallurgical operations including steelmaking, aluminum smelting, and copper refining

Petrochemical plants operating fired heaters, reformers, crackers, and incinerators

Power generation facilities including coal-fired, gas-fired, and biomass power plants

Measurement through flames in high-temperature industrial processes

About SensorMicro

SensorMicro specializes in infrared thermal imaging technology, focusing on the development and improvement of infrared products and application solutions. Our comprehensive product portfolio enables integrators to develop various gas leak detection systems including handheld devices, online monitoring systems, and UAV payloads for industries such as petroleum, natural gas, chemical, power, and environmental monitoring.

Frequently Asked Questions

What are the applications of optical gas imaging infrared camera core?

The LFM330Z5 camera core enables real-time temperature profiling of molten metal, furnace internal condition monitoring, continuous casting process control, fired heater tube wall temperature monitoring, catalytic cracking unit monitoring, and waste incinerator emission and combustion control. It penetrates furnace flames to measure temperature distribution and detect potential issues before they cause production downtime or safety hazards.

Recommended Products