All Products

-

Thermal Camera Core

-

Thermal Security Camera

-

Drone Thermal Camera

-

Plug-in Thermal Camera

-

Cooled Infrared Detectors

-

Cooled Camera Modules

-

Optical Gas Imaging

-

Infrared Thermal Camera Module

-

High Resolution Thermal Camera Module

-

Thermal Camera For Fever Detection

-

Vehicle Mounted Thermal Camera

-

Integrated Dewar Cooler Assembly

-

Uncooled Infrared Detectors

Contact Person :

Wendy Wang

Phone Number :

+86 27 50185150

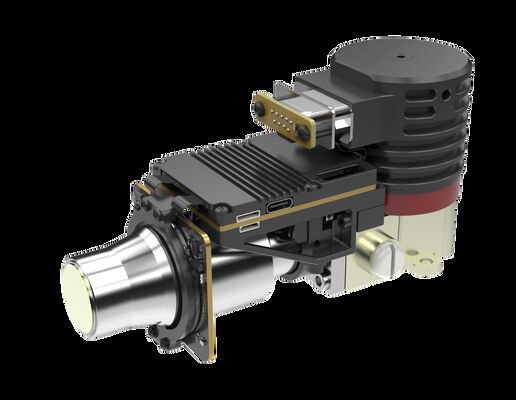

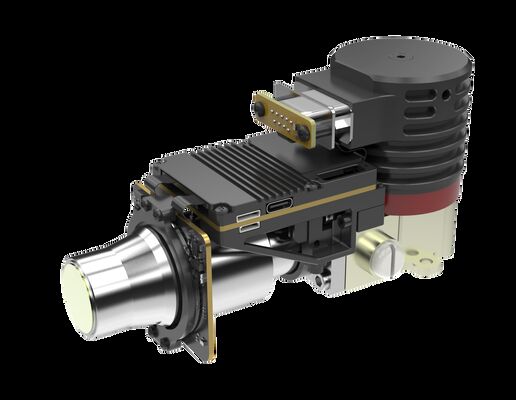

Cooled Optical Gas Imaging MWIR Infrared Camera Core with 320x256/30μm for Measurement through Flames

Product Details

| Function | Measurement Through Flames | Focal Length | 23mm/55mm |

|---|---|---|---|

| Detector Resolution | 320x256 | Pixel Size | 30μm |

| NETD | 20mK (F3) | Spectral Range | 3.8±0.1~4.1±0.1μm |

| Highlight | Optical Gas Imaging MWIR Camera,Cooled Gas Imaging MWIR Camera |

||

Product Description

Cooled Optical Gas Imaging MWIR Infrared Camera Core 320x256 30μm

High-performance thermal imaging camera core designed for measurement through flames in industrial environments

Product Overview

In industrial sites such as metallurgy and petrochemicals, equipment including furnaces, furnace walls, and heating furnaces operate in high-temperature combustion environments with strong flame interference. Traditional detection methods struggle to achieve effective observation of internal structures or surface states under these conditions.

The LFM330Z5 infrared thermal camera core is specifically engineered for high-temperature observation applications in flame environments. With exceptional flame penetration capabilities, it accurately images and monitors high-temperature target surfaces, significantly improving inspection efficiency while effectively reducing operational risks.

Main Features

- Clear gas imaging with high sensitivity optical configuration

- High reliability for demanding industrial applications

- Easy integration supporting various interfaces and RAW/YUV image output

- Wide application scenarios suitable for handheld, mobile, or fixed platforms

Product Specifications

| Module Model | LFM330Z5 |

|---|---|

| Resolution | 320*256 |

| Pixel Size | 30μm |

| Spectral Response | 3.8±0.1μm~4.1±0.1μm |

| Typical NETD | 20mK (F3) |

| Frame Rate | 30Hz/60Hz |

| Digital Video | Standard: DVP/LVDS/USB2.0 Optional: Cameralink/USB3.0/GigE/SDI/MIPI/Single-mode fiber/Multi-mode fiber |

| Communication | Standard: USB2.0/LV-TTL Optional: RS422/CAN/USB3.0/GigE |

| Cooling Time (23℃) | ≤8min@12V |

| Stable Power Consumption (23℃) | ≤10W |

| Size (mm) | 142*58.5*80 |

| Weight (g) | ≤680 |

| Working Temperature | -40℃~+71℃ |

| Focal Length | 23mm/55mm |

Industrial Applications

The LFM330Z5 cooled thermal imaging camera core is used for measurement through flames in various industrial processes:

- Metallurgical operations including steelmaking, aluminum smelting, and copper refining involving high-temperature furnaces, converters, and ladles with intense flames and smoke

- Petrochemical plants operating large-scale fired heaters, reformers, crackers, and incinerators with open flames and heavy smoke

- Coal-fired, gas-fired, and biomass power plants relying on boilers with intense flame combustion

Core Technology

Strong R&D Capabilities: SensorMicro is one of China's earliest companies researching antimonide-based Type-II superlattice (T2SL) cooled infrared detectors, pioneering domestic mass production and engineering applications with proven capabilities in MWIR, LWIR, large-format arrays, and high-operating-temperature detectors.

Leading Technological Achievements: SensorMicro leads the SWaP³ technology development trend, excelling in large-format arrays, small pixel technology, high-temperature operation, miniaturization, high performance, and low power consumption.

Complete Supply Chain: Integrated technology from chip design and cooler manufacturing to high vacuum packaging processes ensures stable supply chain, reliable quality, and significant cost advantages.

Frequently Asked Questions

What are the Principles of Optical Gas Imaging Technology?

With rapid industrial development, toxic and harmful gases may leak during production, transportation, and use, causing fires, explosions, and environmental pollution while threatening personal and property safety.

Optical Gas Imaging (OGI) technology leverages the absorption characteristics of gases toward infrared radiation in specific wavelength bands. By detecting infrared radiation differences between gases and the background environment, it achieves visual imaging of leaked gases. This technology enables quick leak detection without work stoppage, accurate leak source location, and timely hazard identification to prevent accidents.

Recommended Products