All Products

-

Thermal Camera Core

-

Thermal Security Camera

-

Drone Thermal Camera

-

Plug-in Thermal Camera

-

Cooled Infrared Detectors

-

Cooled Camera Modules

-

Optical Gas Imaging

-

Infrared Thermal Camera Module

-

High Resolution Thermal Camera Module

-

Thermal Camera For Fever Detection

-

Vehicle Mounted Thermal Camera

-

Integrated Dewar Cooler Assembly

-

Uncooled Infrared Detectors

Contact Person :

Wendy Wang

Phone Number :

+86 27 50185150

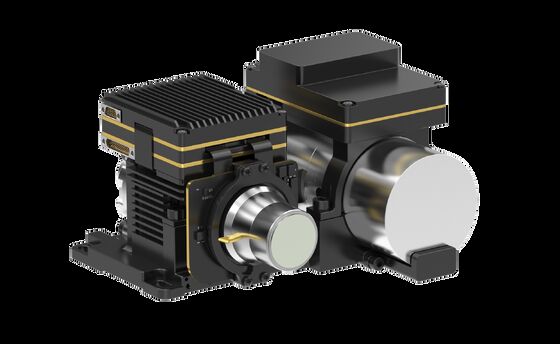

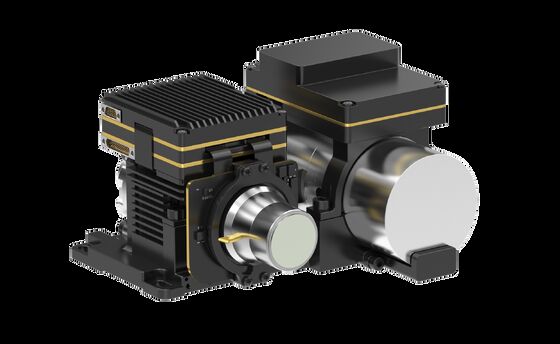

320x256/30μm Cooled Infrared Module for Petrochemical Industry Gas Leak Detection

Product Details

| Style | Cooled Infrared Module | Resolution | 320x256 / 30μm |

|---|---|---|---|

| NETD | 10mK | Spectral Range | 3.2±0.1~3.5±0.1μm |

| Frame Rate | 30Hz | Optional Lens | Fixed Zoom |

| Highlight | 23mm Gas Leak Detection Camera,Petrochemical Gas Leak Detection Camera |

||

Product Description

320x256/30μm Petrochemical Industry Infrared Gas Leak Detection Camera With 23mm Lens

Product Overview

LFM330Z3 gas leak detection camera integrates 320x256 / 30µm MCT cooled MWIR infrared detector and covers mid wavelength from 3.2 to 3.5μm.

This cooled infrared camera module can detect leaks of dozens of volatile organic compounds (VOCs). VOCs are human-made chemicals used in manufacturing paints, pharmaceuticals, and refrigerants, some of which may have short- and long-term adverse health effects.

By using this thermal module, inspectors can quickly detect harmful gas leakage, which plays a very important role in safe production, efficiency improvement and cost saving.

Main Features

- Supporting PAL/NTSC analog video output

- Rich image details meet the needs of rapid gas leakage detection

- Equipped with gas enhanced image algorithm (high sensitivity mode HSM) to enhance image display for subtle leaks

- Supports detection of methane, ethane, propane, butane, pentane, hexane, heptane, octane, ethylene, propylene, isoprene, methanol, ethanol, butanone, benzene, toluene, xylene, ethylbenzene, and more

Product Specifications

| Module model | LFM330Z3 |

|---|---|

| Resolution | 320*256 |

| Pixel size | 30μm |

| Spectral response | 3.2±0.1μm~3.5±0.1μm |

| Typical NETD | 10mK (F1.5) |

| Frame rate | 30Hz |

| Digital video | Standard: DVP/LVDS/USB2.0 Optional: Cameralink/USB3.0/GigE/SDI/MIPI/Single-mode fiber/Multi-mode fiber |

| Communication | Standard: USB2.0/LV-TTL Optional: RS422/CAN/USB3.0/GigE |

| Cryocooler | RS058I | LS713 | LS734 |

| Cooling time (23 ℃) | ≤8min@12V | ≤6.5min@12V | ≤6.5min@24V |

| Stable power consumption (23 ℃) | ≤10W | ≤11W | ≤16W |

| Size (mm) | 142*58.5*80 | 108*116*73 | 130*131*80 |

| Weight (g) | ≤680 | ≤800 | ≤1610 |

| Working temperature | -40℃~+71℃ |

| Focal length | 23mm/55mm/25-75mm |

Industrial Applications

The LFM330Z3 gas leak detection thermal imaging camera is used for visualizing invisible VOCs (volatile organic compounds) and detecting gas leakage including: Methane, Ethane, Propane, Butane, Pentane, Hexane, Heptane, Octane, Ethylene, Propylene, Isoprene, Methanol, Ethanol, Butanone, Benzene, Toluene, Xylene, Ethylbenzene, and more.

Our Advantages

- Strong R&D capabilities: SensorMicro is one of China's earliest companies researching antimonide-based Type-II superlattice (T2SL) cooled infrared detectors, with proven capabilities in R&D and manufacturing of high-end advanced devices.

- Leading technological achievements: Leads SWaP³ technology development, excelling in large-format array, small pixel, high-temperature operation, miniaturization, high performance, and low power consumption.

- Complete supply chain: Integrated technology from chip design to cooler manufacturing and vacuum packaging ensures stable supply, reliable quality, and significant cost advantages.

Frequently Asked Questions

What is a cryocooler used for?

Cryocoolers are machines that keep sensors extremely cold so that thermal images can be taken on long-term missions. In many high-end applications, the sensors that capture images require extremely low temperatures.

What are the main factors to measure the quality of Cryocooler?

Long battery life and reliable operation are main factors to measure the quality of a cryocooler. SensorMicro cryocooler has a wide operating temperature range and excellent reliability. Its MTTF (Mean Time to Failures) has reached to 10,000 hours, which meets 24*7 boot operation requirements.

What is MTTF?

MTTF (Mean Time to Failure) measures a part's reliability. It shows you how long on average a part lasts before it breaks and you have to replace it. On a basic level, it tells you about the quality of the parts you're buying. The longer they last, the more value you're getting from them.

Recommended Products