All Products

-

Thermal Camera Core

-

Thermal Security Camera

-

Drone Thermal Camera

-

Plug-in Thermal Camera

-

Cooled Infrared Detectors

-

Cooled Camera Modules

-

Optical Gas Imaging

-

Infrared Thermal Camera Module

-

High Resolution Thermal Camera Module

-

Thermal Camera For Fever Detection

-

Vehicle Mounted Thermal Camera

-

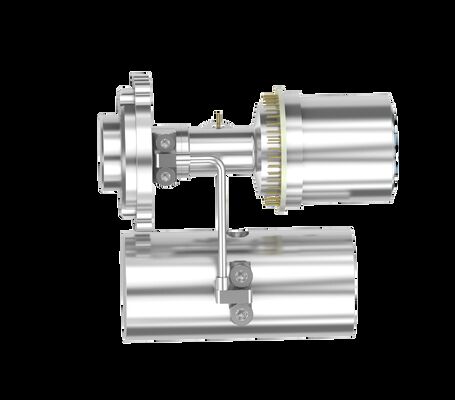

Integrated Dewar Cooler Assembly

-

Uncooled Infrared Detectors

Contact Person :

Wendy Wang

Phone Number :

+86 27 50185150

Cooled MWIR Thermal Imaging Detector with 640×512/15μm for High Sensitivity 25mK NETD Gas Leak Detection

Product Details

| Spectral Range | 3.2±0.1~3.5±0.1μm | Typical NETD | 25mK (F1.5) |

|---|---|---|---|

| Detector Resolution | 640x512 | Pixel Size | 15μm |

| Function | Gas Leak Detection | Weight (g) | ≤235g |

| Highlight | VOCs Visualizing Thermal Imaging Sensor,VOCs MWIR Thermal Imaging Sensor,24VDC Optical Gas Imaging Sensor |

||

Product Description

Cooled MWIR Thermal Imaging Detector 640×512/15μm for Visualizing VOCs in Petrochemical Industry

Volatile organic compounds (VOCs), widely distributed in industries such as petrochemicals, present significant safety risks due to their volatile, flammable, explosive, and toxic nature. Traditional detection methods often suffer from limitations including short detection distances, restricted search ranges, and lack of intuitive visualization.

The LFD615HZ3 infrared detector for gas leak detection leverages industry-leading T2SL technology and HOT device technology, offering superior SWaP³ performance advantages. This enables more precise leak detection, comprehensive coverage of common VOC gas types, and significant improvements in operational safety levels.

Key Features

- SWaP³ Optimization: Smaller size, lighter weight, lower power consumption

- Clear & Identifiable Leakage: 640×512 resolution with gas enhanced HSM algorithm support

- High Reliability & Sensitivity: Superior detection performance

- Easy Integration: Supports various interfaces and RAW/YUV image output

- Full Scene Coverage: Suitable for handheld and long-term online applications

Product Specifications

| Detector model | LFD615HZ3 |

|---|---|

| Resolution | 640×512 |

| Pixel size | 15μm |

| Spectral response | 3.2±0.1μm~3.5±0.1μm |

| Typical NETD | 25mK (F1.5) |

| Cooling time (23℃) | ≤3.5min@20℃@12V |

| Stable power consumption (23℃) | ≤4W |

| Size (mm) | Compressor φ26×56 Dewar φ40×71 |

| Weight (g) | ≤235g |

| Working temperature | -45℃~+71℃ |

| Storage temperature | -55℃~+71℃ |

| MTTF | ≥30000h |

Industrial Applications

The LFD615HZ3 gas leak detection cooled MWIR thermal imaging detector is designed for customers with strong development capabilities. By integrating this cooled thermal sensor, invisible volatile organic compounds (VOCs) can be detected and visualized to prevent further damage. Detection coverage includes gases such as: Methane, Ethane, Propane, Butane, Pentane, Hexane, Heptane, Octane, Ethylene, Propylene, Isoprene, Methanol, Ethanol, Butanone, Benzene, Toluene, Xylene, Ethylbenzene, and more.

Technological Advantages of Optical Gas Imaging

- Non-contact & Remote Detection: Conduct safe, non-destructive testing from dangerous and complex areas

- Quick Leak Source Location: Wide area real-time detection with minimal production interruption

- Gas Leak Visualization: Intuitive display of leakage locations for efficient inspection

- Enhanced Inspection Safety: Reduced accident risk and minimized operational losses

Frequently Asked Questions

What is NETD?

NETD refers to "Noise Equivalent Temperature Difference". It measures a thermal imaging detector's ability to distinguish between very small differences in thermal radiation. NETD is typically expressed in milli-Kelvin (mK), where lower values indicate higher thermal sensitivity.

What is SWaP³?

SWaP³ refers to size, weight, power, performance and price, representing the key technology trends in the infrared industry.

What is DRI?

DRI typically refers to detection, recognition and identification distance of a thermal imaging system, serving as a crucial performance parameter.

How to select the right pseudo color for thermal imaging?

- Gray white is more suitable for targets with small temperature differences

- Red and blue are more suitable for identifying problem points in scenes

- Iron red serves as the standard color palette for the power industry

Note: The thermal temperature remains unchanged regardless of palette selection.

Recommended Products