-

Thermal Camera Core

-

Thermal Security Camera

-

Drone Thermal Camera

-

Plug-in Thermal Camera

-

Cooled Infrared Detectors

-

Cooled Camera Modules

-

Optical Gas Imaging

-

Infrared Thermal Camera Module

-

High Resolution Thermal Camera Module

-

Thermal Camera For Fever Detection

-

Vehicle Mounted Thermal Camera

-

Integrated Dewar Cooler Assembly

-

Uncooled Infrared Detectors

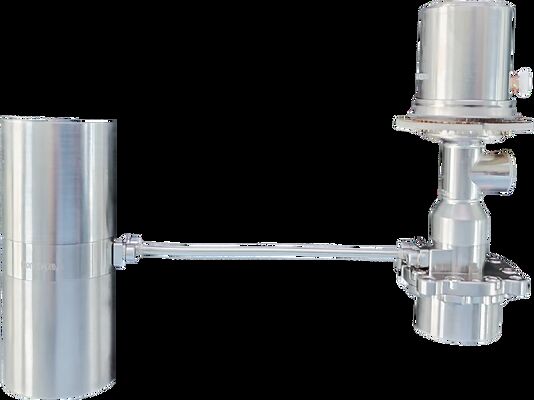

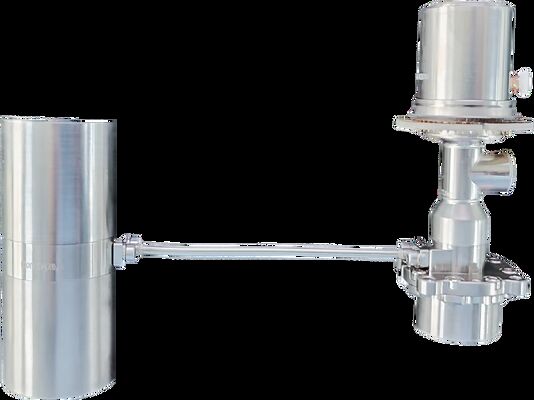

320x256/30μm Cooled MWIR Thermal Imaging Detector with 10mK NETD for VOCs Gas Leak Detection

| Spectral Range | 3.2±0.1~3.5±0.1μm | Detector Resolution | 320x256 |

|---|---|---|---|

| Pixel Size | 30μm | Function | Gas Leak Detection |

| Cryo Cooler | RS058I/LS713/LS734 | NETD | 10mK |

| Highlight | MWIR Thermal Imaging Detector,320x256 Thermal Imaging Detector |

||

320x256/30 μm MWIR Cooled Thermal Imaging Detector for Visualizing Gas Leaks

In the petrochemical industry, gas leak detection scenarios occur frequently. Traditional detection devices have limited detection distance and low detection efficiency, making it difficult to achieve intuitive and accurate identification of common VOCs gas leaks such as methane and benzene.

The LFD330Z3 cooled infrared detector for gas leak detection is specially developed for VOCs gas leak detection with the function of converting infrared radiation of targets with 3.2~3.5μm wavelength into electrical signals. Its external mechanical interface, optical interface and electronic interface are commonly used and can be expanded. It can remotely and visually detect minor leaks of VOCs gases such as methane, benzene, and ethanol, achieving efficient gas operation monitoring and safety production warning.

LFD330Z3 is widely used in atmospheric environment monitoring and gas leakage detection, pollutant discharge, and chemical gas detection in petrochemical plants and refineries.

- Optical Gas Imaging - Long range non-contact detection with high efficiency, security and wide range of gas leak detection

- High Sensitivity - High sensitive cooled infrared detector, quite efficient in application of low gas concentration and slow gas flow

- Designed for User Requirements - Various cryocoolers available for light weight, low power, long life and high reliability

| Parameter | Specification |

|---|---|

| Detector model | LFD330Z3 |

| Resolution | 320*256 |

| Pixel size | 30μm |

| Spectral response | 3.2±0.1μm~3.5±0.1μm |

| Typical NETD | 10mK (F1.5) |

| Cryocooler options | RS058I | LS713 | LS734 |

| Cooling time (23℃) | ≤7min@12V | ≤5min@12V |

| Power consumption (23℃) | ≤13W (Peak) ≤7W (Stable) | ≤18W (Peak) ≤7W (Stable) | ≤35W (Peak) ≤15W (Stable) |

| Size (mm) | 142*58.5*71 | Compressor φ33.5*68 Dewar φ41*86 | Compressor φ46*122 Dewar φ46.5*112 |

| Weight (g) | ≤600 | ≤350 | ≤1200 |

| Working temperature | -45℃~+71℃ |

| Storage temperature | -55℃~+71℃ |

| MTTF | ≥10000h | ≥30000h |

The LFD330Z3 gas leak detection cooled MWIR thermal imaging detector is designed for customers with strong development capabilities. By integrating this cooled thermal sensor, invisible VOCs (volatile organic compounds) can be detected and visualized to prevent further damage.

Detectable gases include: Methane, Ethane, Propane, Butane, Pentane, Hexane, Heptane, Octane, Ethylene, Propylene, Isoprene, Methanol, Ethanol, Butanone, Benzene, Toluene, Xylene, Ethylbenzene, and others.

With the rapid development of human society and economy and the continuous acceleration of industrialization, a large amount of toxic and harmful gases may leak during production, transportation, and use, causing disasters such as fires and explosions. While polluting the atmospheric environment, it also poses a great threat to personal and property safety.

Optical Gas Imaging (OGI) technology is based on the absorption characteristics of gases toward infrared radiation in a specific wavelength band. By detecting the difference in infrared radiation between gases and the background environment, it achieves visual imaging of leaked gases. This technology can quickly detect the presence of leaked gas without stopping work, accurately locate the source of the leak, promptly detect safety hazards, and avoid accidents.

In which industries can the infrared detectors / thermal camera cores be used?

SensorMicro thermal camera modules are widely used in many industries such as:

- Thermography: Power Maintenance, Machine Vision, Building HVAC, Metallurgical Petrochemical, Predictive Maintenance, Epidemic Prevention

- Security & Monitoring: Safe City, Infrastructure Monitoring, Border Security, Maritime Cruising, Mining Safety

- Firefighting & Rescue: Forest Fire Prevention, Fire Prevention, Search & Rescue

- UAVs payload: Equipment Inspection, Enforcement & Rescue, Firefighting Application, Animal Observation

- Personal Vision: Outdoor Leisure, Animal Observation, Enforcement Patrol

- ADAS: Autonomous Driving, Advanced Driver Assistant System, Special Vehicles

- AIoT: Smart Home, Intelligent Hardware, Smart Care, Robots

- Others: Enhanced Flight Vision System, Gas Detection, Agriculture & Graziery, Scientific Research