-

Thermal Camera Core

-

Thermal Security Camera

-

Drone Thermal Camera

-

Plug-in Thermal Camera

-

Cooled Infrared Detectors

-

Cooled Camera Modules

-

Optical Gas Imaging

-

Infrared Thermal Camera Module

-

High Resolution Thermal Camera Module

-

Thermal Camera For Fever Detection

-

Vehicle Mounted Thermal Camera

-

Integrated Dewar Cooler Assembly

-

Uncooled Infrared Detectors

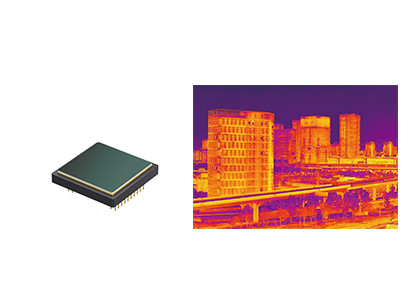

400x300/12μm Uncooled FPA Thermal Imaging Detector with Ceramic Package

| Resolution | 400x300 / 12μm | NETD | <40mK |

|---|---|---|---|

| Spectral Range | 8~14μm | Size | 18.5×18.5×3.8 (Without Pin Size) |

| Highlight | Uncooled FPA Thermal Imaging Detector,400x300 Thermal Imaging Detector,12um Uncooled Infrared Detectors |

||

400x300/12μm Uncooled FPA Thermal Imaging Detector with Ceramic Package

GST412C uncooled infrared detector is a new arrival infrared product developed by SensorMicro. It uses the international mainstream vanadium oxide material which makes it own more outstanding comprehensive performance. This vanadium oxide (VOx) microbolometer detector covers long wavelength from 8 to 14μm. And its resolution is 400x300 with pixel size at 12μm.

Ceramic packaging is currently the most popular packaging technology on the market. The size, weight and power consumption of the detector can be significantly reduced. By integrating the ceramic packaging infrared detector, the infrared camera could present clear and sharp images.

This new ceramic package infrared detector will give more choices for customers from various industries such as Industrial Automation, Intelligent Security, Unmanned Platform, Robot, Intelligent Hardware, Advanced Driver Assistant System, Firefighting etc.

- High thermal sensitivity, NETD<40mK

- Frame rate up to 50Hz;

- Mini size as low as 18.5mm×18.5mm×3.8mm

- Light weight, less than 4.5g

- Low power consumption: 80mW

| Model | GST412C |

| Sensitive Material | Vanadium Oxide |

| Resolution | 400×300 |

| Pixel Size | 12μm |

| Spectral Range | 8-14μm |

| Typical NETD | <40mK |

| Digital Output | Built-in 14 bit ADC |

| Thermal Response Time | <12ms |

| Max Frame Rate | 50Hz |

| Power Consumption | ≤80mW |

| Dimension (mm) | 18.5×18.5×3.8 (Without Pin Size) |

| Weight | <4.5g |

| Operating Temperature | -40°C ~ +85°C |

The GST412C thermal imaging detector is widely used in many areas, such as ADAS, Security Monitoring, Handheld Device, Helmet-mounted Device, UAV Payloads, Machine Vision, Thermography, Power Maintenance, Metallurgy Petrochemical, Epidemic Prevention, Scientific Research etc.

• Deep Technical Expertise

With many years of experience in the research, development, and application of infrared sensor technology, we have built strong capabilities across chip design, wafer fabrication, packaging and testing, as well as system integration. Our solid foundation enables us to continuously deliver innovative and reliable products that meet evolving market demands.

• Focused on Innovation and Practical Implementation in Infrared Sensing

We are committed to driving technological breakthroughs in thermal imaging, constantly pushing the boundaries in NETD,SWaP,and operating temperature. Our products consistently lead in applications across security, industrial monitoring, intelligent systems, and more.

• Diversified Product Portfolio

Backed by independent R&D and multiple technical pathways, we offer a comprehensive range of infrared detection components—both cooled and uncooled—providing tailored solutions for a wide variety of industries.

• Rigorous Reliability Validation Ensures Quality Assurance

Supported by a robust quality management system, our products undergo multiple testing procedures throughout production to ensure long-term stability and reliability.

• Professional Technical Support and Joint Development Services

Our engineering team works closely with customers’ R&D and product teams to accelerate system integration, improve efficiency, and shorten time-to-market. Your success is our shared mission.

1.What is infrared thermal imaging?

Infrared thermal imaging is a method of using infrared radiation and thermal energy to gather information about objects, in order to formulate images of them, or get temperature information of the objects, even in low visibility environments.

2.How does Infrared Thermal Imaging Work?

Infrared thermal imaging system is a passive non-contact detection and identification of infrared technology. It focuses the infrared radiation of the scene on the focal plane array infrared detector through the infrared optical system that can pass through infrared radiation. The thermal detector converts the radiation signal of different intensity into the corresponding electrical signal, and then through amplification and video processing, forms the infrared image that can be observed by the naked eyes.