All Products

-

Thermal Camera Core

-

Thermal Security Camera

-

Drone Thermal Camera

-

Plug-in Thermal Camera

-

Cooled Infrared Detectors

-

Cooled Camera Modules

-

Optical Gas Imaging

-

Infrared Thermal Camera Module

-

High Resolution Thermal Camera Module

-

Thermal Camera For Fever Detection

-

Vehicle Mounted Thermal Camera

-

Integrated Dewar Cooler Assembly

-

Uncooled Infrared Detectors

Contact Person :

Wendy Wang

Phone Number :

+86 27 50185150

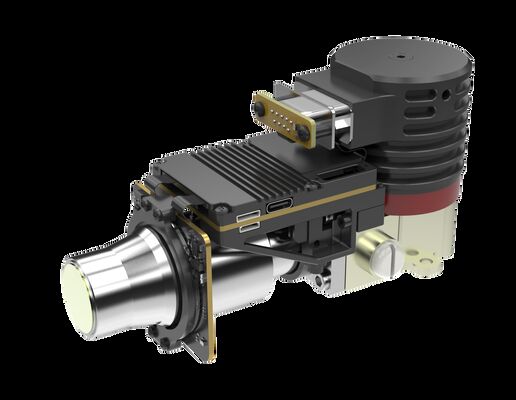

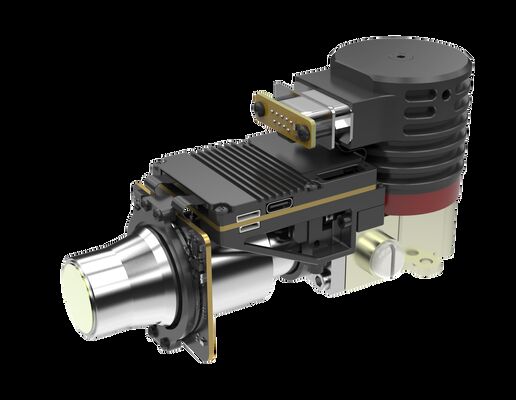

320x256 Resolution 60Hz Frame Rate 20mK NETD Cooled Optical Gas Imaging Thermal Module for Gas Leak Detection

Product Details

| Function | Gas Leak Detection | Spectral Range | 10.3±0.1μm~10.9±0.1μm |

|---|---|---|---|

| Frame Rate | 60Hz | Detector Resolution | 320x256 |

| NETD | 20mK (F1.5) | Pixel Size | 30μm |

| Highlight | Optical Gas Imaging Thermal Module,320x256 Optical Gas Imaging,MWIR Gas Thermal Imaging Module |

||

Product Description

320x256 LWIR Cooled Optical Gas Imaging Thermal Module for Visualizing Gas Leaks

Product Overview

The LFD330C2 infrared detector and matching LFM330C2 thermal module are engineered for precise gas leak detection using advanced Type II Superlattice (T2SL) technology. This system delivers exceptional performance in sensitivity, stability, and integration flexibility, making it the ideal solution for detecting critical industrial gases including sulfur hexafluoride (SF₆), ammonia, and ethylene.

Key Features

- Advanced T2SL Technology: Built on Type II Superlattice foundation with high quantum efficiency

- Easy Integration: Supports multiple interfaces with RAW/YUV image output compatibility

- High Sensitivity: Superior detection capabilities for precise gas visualization

Technical Specifications

| Module Model | LFM330C2 |

|---|---|

| Resolution | 320×256 |

| Pixel Size | 30μm |

| Spectral Response | 10.3±0.1μm~10.9±0.1μm |

| Typical NETD | 20mK (F1.5) |

| Frame Rate | 60Hz |

| Digital Video Interfaces | Standard: DVP/LVDS/USB2.0 Optional: Cameralink/USB3.0/GigE/SDI/MIPI/Single-mode fiber/Multi-mode fiber |

| Communication Interfaces | Standard: USB2.0/LV-TTL Optional: RS422/CAN/USB3.0/GigE |

| Cooling Time (23℃) | ≤8min@24V |

| Stable Power Consumption (23℃) | ≤13W |

| Dimensions | 142×58.5×80 mm |

| Weight | ≤680g |

| Operating Temperature | -40℃~+71℃ |

| Focal Length | 25mm |

Industrial Applications

The LFM330C2 thermal imaging camera is specifically designed for detecting gas leaks in industrial environments, including but not limited to:

- Sulfur hexafluoride (SF₆)

- Anhydrous ammonia (NH₃)

- Ethylene and propene

- Various Freon compounds

- Industrial solvents and chemicals

- Volatile organic compounds

Company Strengths

• Diversified Product Portfolio

• Deep Technical Expertise

• Rigorous Reliability Validation Ensures Quality Assurance

• Focused on Innovation and Practical Implementation in Infrared Sensing

• Professional Technical Support and Joint Development Services

• Deep Technical Expertise

• Rigorous Reliability Validation Ensures Quality Assurance

• Focused on Innovation and Practical Implementation in Infrared Sensing

• Professional Technical Support and Joint Development Services

Frequently Asked Questions

What is an infrared detector / thermal imaging sensor?

Infrared waves cannot be seen with the human eye. Infrared detectors and thermal imaging sensors are optical-electrical devices that react to infrared radiation and thermal energy, converting it into electrical signals that output visible thermal images.

What is WLP (Wafer Level Package)?

WLP refers to wafer level packaging. It is the process of completing high vacuum packaging directly on the entire MEMS wafer, then scribing and cutting to produce individual infrared sensors. Together with metal and ceramic packaging, these represent the three main package formats for uncooled infrared detectors.

What are the advantages of WLP?

WLP infrared detectors are specifically designed to meet miniaturization and cost requirements for infrared technology applications in consumer electronics markets. With volume fabrication capability, we offer various WLP infrared module solutions to drive new applications in emerging markets.

What is infrared thermal imaging?

Infrared thermal imaging is a method of using infrared radiation and thermal energy to gather information about objects, enabling image formulation or temperature measurement even in low visibility environments.

How does Infrared Thermal Imaging Work?

Infrared thermal imaging systems use passive non-contact detection technology. They focus infrared radiation from the scene onto a focal plane array detector through infrared optical systems. The thermal detector converts varying radiation intensities into corresponding electrical signals, which are then amplified and processed to form visible infrared images.

What are the main factors to measure the quality of a Cryocooler?

Long battery life and reliable operation are the primary factors for evaluating cryocooler quality. Our cryocoolers feature wide operating temperature ranges and excellent reliability, with MTTF (Mean Time to Failures) reaching 10,000 hours to meet 24/7 continuous operation requirements.

Recommended Products