-

Thermal Camera Core

-

Thermal Security Camera

-

Drone Thermal Camera

-

Plug-in Thermal Camera

-

Cooled Infrared Detectors

-

Cooled Camera Modules

-

Optical Gas Imaging

-

Infrared Thermal Camera Module

-

High Resolution Thermal Camera Module

-

Thermal Camera For Fever Detection

-

Vehicle Mounted Thermal Camera

-

Integrated Dewar Cooler Assembly

-

Uncooled Infrared Detectors

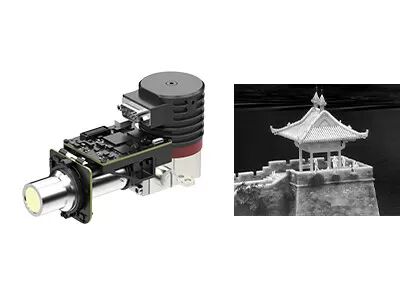

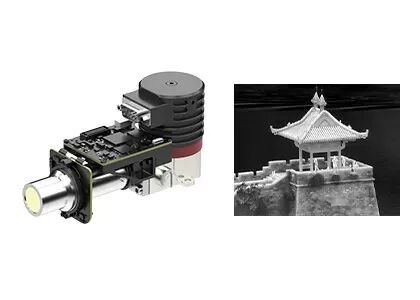

RS058 T2SL Thermal Camera Core 640x512 15μm Cooled Infrared Detector Integration

| Resolution | 640x512 / 15μm | NETD | ≤25mK |

|---|---|---|---|

| Spectral Range | 7.7~9.5μm (LW) | Frame Rate | 1~160Hz Adjustable |

| Size | 148x58.5x71mm | Weight | ≤680g |

| Highlight | RS058 Thermal Camera Core,680g Cooled Infrared Detector Integration,640x512 Thermal Camera Core |

||

Accelerator for 640x512 / 15μm RS058 T2SL LWIR Cooled Infrared Detector Integration

EYAS series cooled AD modules have the pre-amplifier function to convert the analog signal from cooled IR detectors into a digital video stream output. It is available with different resolution formats and different wave bands. EYAS615L is a member of EYAS family with 640x512 / 15μm T2SL LWIR infrared detector and RS058 cryocooler integrated.

EYAS615L AD module features in frame rate up to 160Hz, which is ideal for applications that require observation on fast moving objects. The proximity board comes with EYAS615L makes it an accelerator for OEM customers to carry out fast acceptance test on infrared detectors, start rapid secondary development and shorten their development period of modules and complete products based on cooled infrared detectors.

- Easy to Develop & Integrate

- Cameralink Interface Output 16bit Raw Data, Serial Port Control

- Integrated Structure, Dimensions are Consistent with Detector

- 5V Single-supply

- Capable of Capturing High Speed Moving Target

| Model | EYAS615L |

| IR Detector Performance | |

| Resolution | 640x512 |

| Pixel Pitch | 15μm |

| Cryocooler | RS058 |

| Spectral Range | 7.7μm~9.5μm LW |

| Cooling Time (25°C) | ≤5.5min |

| Optimal NETD (20°C) | ≤25mK |

| Working Mode | |

| Frame Rate | 1~160Hz Adjustable |

| Working Mode | Snapshot; ITR & Interlace Binning Integration Mode; Windows Mode; Anti-blooming |

| Electrical Specification | |

| Standard External Interface | QSH 60pin |

| Digital Video | Cameralink: Output 16bit Raw Data |

| External Sync | CC1: INT/Frame External Sync; CC2: MC External Sync |

| Communication | Cameralink Serial Port: TFG+/-, TC+/-; 9600bps |

| Power Supply | 1 Channel Imaging Panel: 5V 1 Channel Cryocooler: 24V |

| Stable Power Consumption | 9W |

| Dimension (mm) | 148×58.5×71 |

| Weight | ≤680g |

| Working Temperature | -40°C ~ +60°C |

| Vibration Magnitude | Vibration: GJB Vehicle-mounted High Speed Transport Shock: Half-sine Wave, 40g 11 ms, 3 Axis 6 Direction 3 Times Each |

The EYAS615L thermal imaging module is widely used many areas such as Remote Monitoring System, Flight Vision Enhancement System, Multi-sensor Payload etc.

![]()

Our Product Line

High sensitivity and excellent performance

World-leading technology in infrared industry

Various infrared detectors available

Both uncooled and cooled lR detectors in different formats and pixel size

Volume production to ensure fast delivery

Three production lines with annual production capability up to millions of detectors.

1. How to choose proper infrared detector resolution?

It depends on the actual needs and applications of your products, and the price is also a factor that needs to be considered. If the image quality is not high, you can choose the infrared detector with low resolution, such as 120x90, 256x192, 400x300. If you need a very clear image for some special purposes, such as remote monitoring, you can choose a high resolution infrared detector of 1280x1024.

2. How to select right pseudo color for thermal imaging?

- The gray white is more suitable for the target with small temperature difference

- The red and blue is more suitable for the scene where the problem points need to be found.

- The iron red is the standard color palette of the power industry.

Note: no matter which palette you choose, the thermal temperature will not change at all.

3. How to choose a suitable infrared thermal camera lens?

- Standard lens can meet normal targets with appropriate distance

- For the telephoto lens, it’s suitable for targets that is relatively small and needs to be viewed from a long distance

- To see more detail of objects at close distance, wide angle lens is better.

- Macro lens is for seeing very tinny target with close distance, such as chip circuit.