-

Thermal Camera Core

-

Thermal Security Camera

-

Drone Thermal Camera

-

Plug-in Thermal Camera

-

Cooled Infrared Detectors

-

Cooled Camera Modules

-

Optical Gas Imaging

-

Infrared Thermal Camera Module

-

High Resolution Thermal Camera Module

-

Thermal Camera For Fever Detection

-

Vehicle Mounted Thermal Camera

-

Integrated Dewar Cooler Assembly

-

Uncooled Infrared Detectors

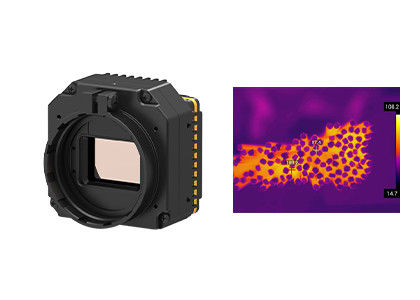

640x512/12μm IR Thermal Camera Core for Industrial Temperature Measurement

| Resolution | 640x512 / 12μm | Temperature Accuracy | ±2℃ Or ±2% |

|---|---|---|---|

| NETD | <30mK | Spectral Range | 8~14μm |

| Size | 44.5x44.5x33.6mm | Weight | ≤85g |

| Highlight | 640x512 Thermal Camera Core,GST Thermal Camera Core |

||

640x512/12μm Infrared Thermal Camera Core for Industrial Temperature Measurement

PLUG612R is one of the PLUG series uncooled infrared modules. It consists of 640x512/12μm uncooled thermal infrared detector, full series of optical components, professional signal processing circuit and image processing algorithm.

PLUG612R is a kind of uncooled infrared thermal imaging module applied in the field of industrial thermal imaging and temperature measurement. The temperature range is customizable, which can meet the specific requirements of industrial thermography and present a clear infrared thermal image.

We are committed to opening a new vision for industrial temperature measurement. After years of technical accumulation and practical experience in the field of infrared temperature measurement, we have provided our customers a full range of machine thermal imaging vision solutions.

- NETD<30mk, High Sensitivity

- Stable Performance

- Easy Integration

- Clear Image Quality & Details

- Customizable Temperature Range

- Strong Environmental Adaptability

| Model | PLUG612R |

| IR Detector Performance | |

| Resolution | 640x512 |

| Pixel Pitch | 12μm |

| Spectral Range | 8~14μm |

| NETD | <30mk |

| Image Processing | |

| Frame Rate | 25Hz/30Hz |

| Start-up Time | <10s |

| Analog Video | PAL/NTSC |

| Digital Video | Y16/YUV/BT656/LVDS |

| Extension Component | USB/Camerlink |

| Dimming Mode | Linear/Histogram/Mixed |

| Digital Zoom | 1~8X Continual Zoom, Step Size 1/8 |

| Image Display | Black Hot/White Hot/Pseudo Color |

| Image Direction | Horizontally/Vertically/Diagonally Flip |

| Image Algorithm | NUC/AGC/IDE |

| Electrical Specification | |

| Standard External Interface | 50pin_HRS Interface |

| Communication Mode | RS232-TTL, 115200bps |

| Supply Voltage | 4~6V |

| Temperature Measurement | |

| Operating Temperature Range | -10°C~50°C |

| Temperature Range | -20°C~150°C, 100°C~550°C |

| Temperature Accuracy | ±2°C or ±2% (Take the Maximum Value) |

| SDK | ARM/Windows/Linux SDK, Full Screen Thermography |

| Physical Characteristics | |

| Dimension (mm) | 44.5x44.5x36.6 |

| Weight | ≤85g |

| Environmental Adaptation | |

| Operation Temperature | -40°C ~ +70°C |

| Storage Temperature | -45°C ~ +85°C |

| Humidity | 5%~95%, Non-condensing |

| Vibration | Random Vibration 5.35grms, 3 Axis |

| Shock | Half-sine Wave, 40g/11ms, 3 Axis 6 Direction |

| Optics | |

| Optional Lens | Fixed Focus Athermal: 13mm/19mm/24mm |

The PLUG612R thermal module is widely used in Electric Power Inspection, Machine Vision, Building HVAC Security & Monitoring, Outdoors, Firefighting & Rescue, Law Enforcement & Rescue, ADAS, UAV Payloads etc.

![]()

Your Trusted Partner in Infrared Sensing

• Deep Technical Expertise

With many years of experience in the research, development, and application of infrared sensor technology, we have built strong capabilities across chip design, wafer fabrication, packaging and testing, as well as system integration. Our solid foundation enables us to continuously deliver innovative and reliable products that meet evolving market demands.

• Focused on Innovation and Practical Implementation in Infrared Sensing

We are committed to driving technological breakthroughs in thermal imaging, constantly pushing the boundaries in NETD,SWaP,and operating temperature. Our products consistently lead in applications across security, industrial monitoring, intelligent systems, and more.

• Diversified Product Portfolio

Backed by independent R&D and multiple technical pathways, we offer a comprehensive range of infrared detection components—both cooled and uncooled—providing tailored solutions for a wide variety of industries.

• Rigorous Reliability Validation Ensures Quality Assurance

Supported by a robust quality management system, our products undergo multiple testing procedures throughout production to ensure long-term stability and reliability.

• Professional Technical Support and Joint Development Services

Our engineering team works closely with customers’ R&D and product teams to accelerate system integration, improve efficiency, and shorten time-to-market. Your success is our shared mission.

1. What is the difference between uncooled and cooled IR detectors?

There are currently two types of infrared thermal imaging sensors on the market, cooled and uncooled.

Uncooled IR detector operates at ambient temperature. It is based on semi-conductor industry and thus usually can be fabricated in big volume with small size and low cost. Uncooled IR detectors are widely used in portable/handheld/mobile devices.

Cooled IR detectors are packaged in a unit that keeps them at an extremely low temperature which shall be supported by a cryo cooler. They are much bigger, more expensive and less reliable than uncooled sensors, mainly due to the complex cooling systems they require. However, the cooled systems are incredibly sensitive and usually work with long focal length optics to achieve long range mission.