All Products

-

Thermal Camera Core

-

Thermal Security Camera

-

Drone Thermal Camera

-

Plug-in Thermal Camera

-

Cooled Infrared Detectors

-

Cooled Camera Modules

-

Optical Gas Imaging

-

Infrared Thermal Camera Module

-

High Resolution Thermal Camera Module

-

Thermal Camera For Fever Detection

-

Vehicle Mounted Thermal Camera

-

Integrated Dewar Cooler Assembly

-

Uncooled Infrared Detectors

Contact Person :

Wendy Wang

Phone Number :

+86 27 50185150

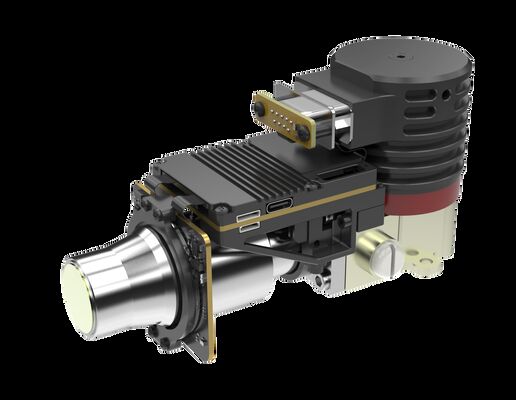

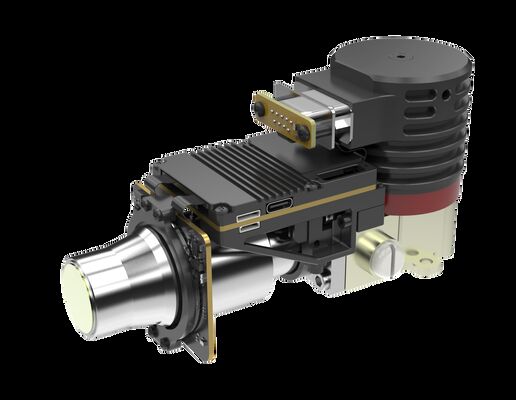

Cooled Optical Gas Imaging Camera with 320x256/30μm and 10mK NETD for Gas Leak Detection

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Function | Gas Leak Detection | Stable Power Consumption (23 ℃) | ≤10W |

|---|---|---|---|

| Spectral Range | 4.2±0.1μm~4.4±0.1μm | Detector Resolution | 320x256 |

| Pixel Size | 30μm | NETD | 10mK (F1.5) |

| Highlight | MWIR Thermal Module 320x256,Cooled MWIR Thermal Module,Gas Imaging MWIR Module |

||

Product Description

Cooled Optical Gas Imaging MWIR Thermal Camera Module 320x256/30μm

Driven by improvements in production methods, the production and use of industrial gas has grown rapidly. While bringing benefits to factories, the hidden danger of gas leakage is also increasingly serious. Optical gas imaging (OGI) is a commonly utilized and very effective method for detecting gas leaks in industrial facilities.

The LFM330Z6 infrared gas leak detection camera core developed by SensorMicro is specifically designed for detecting minute fugitive emissions of industrial gases. With a 320x256/30µm cooled infrared detector, it operates in the spectral range of 4.2±0.1μm~4.4±0.1µm for CO₂ gas leak detection.

SensorMicro has many years of experience in infrared thermal imaging solutions and numerous successful integration cases for gas leak detection. We are confident in providing you with satisfactory service.

Main Features

- Clear detection of leaks with high effective pixel rate

- Equipped with gas enhanced HSM algorithm (for module)

- High sensitivity for precise detection

- High reliability in demanding environments

- Easy integration with support for various interfaces

- RAW/YUV image output compatibility

Product Specifications

| Module model | LFM330Z6 |

| Resolution | 320*256 |

| Pixel size | 30μm |

| Spectral response | 4.2±0.1μm~4.4±0.1μm |

| Typical NETD | 10mK (F1.5) |

| Frame rate | 30Hz/60Hz |

| Digital video | Standard: DVP/LVDS/USB2.0 Optional: Cameralink/USB3.0/GigE/SDI/MIPI/Single-mode fiber/Multi-mode fiber |

| Communication | Standard: USB2.0/LV-TTL Optional: RS422/CAN/USB3.0/GigE |

| Cooling time (23 ℃) | ≤8min@12V |

| Stable power consumption (23 ℃) | ≤10W |

| Size (mm) | 142*58.5*80 |

| Weight (g) | ≤680 |

| Working temperature | -40℃~+71℃ |

| Focal length | 23mm/55mm |

Industrial Applications

The LFM330Z6 gas leak detection thermal imaging detector is used for reliable visualization of invisible CO₂ plumes even in harsh environments: Carbon Capture, Utilization and Storage (CCUS), Enhanced Oil Recovery (EOR), Power Generation Industry, Food & Beverage Industry, Semiconductor & Electronics Manufacturing, Greenhouse Agriculture, Waste Treatment & Biogas Plants, and more.

Our Strengths

- Diversified Product Portfolio

- Deep Technical Expertise

- Rigorous Reliability Validation Ensures Quality Assurance

- Focused on Innovation and Practical Implementation in Infrared Sensing

- Professional Technical Support and Joint Development Services

Frequently Asked Questions

Advantages of Optical Gas Imaging

- Time-saving & Efficient: Supports large-scale real-time detection, rapid leak location, no need for interrupting production

- Long Range Detection: Operates away from dangerous and complex areas, non-contact non-destructive testing, without additional radiation source

- Easy to Analyze: Intuitive imaging, instant storage, convenient analysis

- Multi-function Inspection: Multiple gases can be detected with excellent remote temperature measurement function

Working Principle of Optical Gas Imaging

Optical gas imaging is an infrared technology that visualizes invisible industrial gases. After absorbing infrared radiation at specific wavelengths, infrared radiation differences occur between the gas and the background. The gas leak detection infrared detector with built-in narrowband filter only receives the infrared band near the gas infrared absorption peak, converting the gas into visible infrared images through the radiation difference between the gas and the background.

Recommended Products