All Products

-

Thermal Camera Core

-

Thermal Security Camera

-

Drone Thermal Camera

-

Plug-in Thermal Camera

-

Cooled Infrared Detectors

-

Cooled Camera Modules

-

Optical Gas Imaging

-

Infrared Thermal Camera Module

-

High Resolution Thermal Camera Module

-

Thermal Camera For Fever Detection

-

Vehicle Mounted Thermal Camera

-

Integrated Dewar Cooler Assembly

-

Uncooled Infrared Detectors

Contact Person :

Wendy Wang

Phone Number :

+86 27 50185150

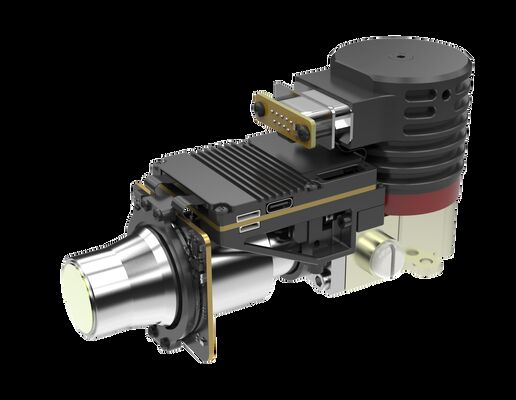

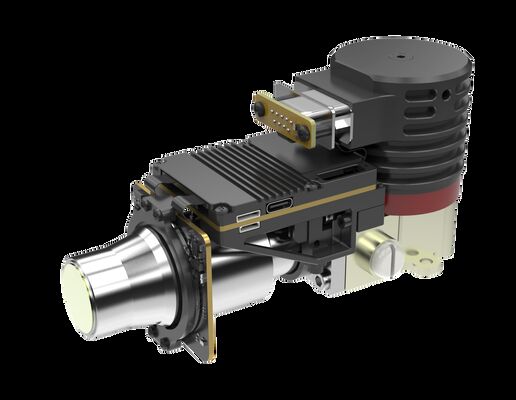

LFM330Z6 320x256/30μm 10mK NETD Infrared Camera Core for Gas Leakage Detection

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Type | Optical Gas Imaging Thermal Module | Wave Band | Mid Wavelength |

|---|---|---|---|

| Resolution | 320x256 / 30μm | Size | 142mm×58.5mm×80mm |

| NETD | 10mK (F1.5) | Spectral Range | 4.2±0.1μm~4.4±0.1μm |

| Highlight | GST Gas Leakage Camera Core,320x256 Gas Leakage Camera Core,30uM Infrared Detector Camera Core |

||

Product Description

LFM330Z6 Gas Leakage Detection Infrared Camera Core

Product Overview

The LFM330Z6 infrared gas leak detection camera core is specifically designed for detecting minute fugitive emissions of industrial gases. Featuring a 320x256/30µm cooled infrared detector, it operates in the spectral range of 4.2±0.1μm~4.4±0.1μm for precise CO₂ gas leak detection.

This real-time non-contact measurement system enables inspectors to detect gas leaks in hazardous areas or hard-to-access locations, ensuring personnel safety while providing significant value in safety production, environmental protection supervision, and cost reduction.

Key Features

- High Sensitivity: Cooled infrared detector with NETD of 10mK (F1.5), highly effective for low gas concentration and slow gas flow applications

- Easy Integration: Multiple image output interfaces including Cameralink/DVP/USB/Gig-E, compatible with various development environments

- Flexible Configuration: Multiple lens options with various fields of view for diverse application scenarios

Technical Specifications

| Module Model | LFM330Z6 |

|---|---|

| Resolution | 320*256 |

| Pixel Size | 30μm |

| Spectral Response | 4.2±0.1μm~4.4±0.1μm |

| Typical NETD | 10mK (F1.5) |

| Frame Rate | 30Hz/60Hz |

| Digital Video Interfaces | Standard: DVP/LVDS/USB2.0 Optional: Cameralink/USB3.0/GigE/SDI/MIPI/Single-mode fiber/Multi-mode fiber |

| Communication Interfaces | Standard: USB2.0/LV-TTL Optional: RS422/CAN/USB3.0/GigE |

| Cooling Time (23℃) | ≤8min@12V |

| Stable Power Consumption (23℃) | ≤10W |

| Size | 142*58.5*80 mm |

| Weight | ≤680 g |

| Working Temperature | -40℃~+71℃ |

| Focal Length | 23mm/55mm |

Industrial Applications

The LFM330Z6 gas leak detection thermal imaging detector provides reliable visualization of invisible CO₂ plumes even in harsh environments. Applications include Carbon Capture, Utilization and Storage (CCUS), Enhanced Oil Recovery (EOR), Power Generation Industry, Food & Beverage Industry, Semiconductor & Electronics Manufacturing, Greenhouse Agriculture, and Waste Treatment & Biogas Plants.

Customer Feedback

Frequently Asked Questions

Advantages of Optical Gas Imaging

- Time-saving & Efficient: Supports large-scale real-time detection with rapid leak location, no production interruption required

- Long Range Detection: Operates from safe distances in hazardous areas with non-contact, non-destructive testing

- Easy to Analyze: Intuitive imaging with instant storage and convenient analysis capabilities

- Multi-function Inspection: Detects various gases while providing excellent remote temperature measurement functionality

Working Principle of Optical Gas Imaging

Optical gas imaging utilizes infrared technology to visualize invisible industrial gases. When gases absorb infrared radiation at specific wavelengths, they create infrared radiation differences between the gas and background. The gas leak detection infrared detector, equipped with a built-in narrowband filter, captures the infrared band near the gas absorption peak and converts gas emissions into visible infrared images through radiation differential analysis.

Recommended Products