-

Thermal Camera Core

-

Thermal Security Camera

-

Drone Thermal Camera

-

Plug-in Thermal Camera

-

Cooled Infrared Detectors

-

Cooled Camera Modules

-

Optical Gas Imaging

-

Infrared Thermal Camera Module

-

High Resolution Thermal Camera Module

-

Thermal Camera For Fever Detection

-

Vehicle Mounted Thermal Camera

-

Integrated Dewar Cooler Assembly

-

Uncooled Infrared Detectors

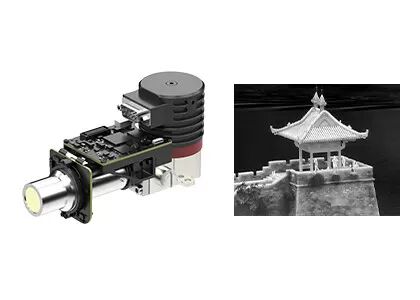

640x512 15μm Cooled Camera Modules RS058 T2SL LWIR Camera Core

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Resolution | 640x512 / 15μm | NETD | ≤25mK |

|---|---|---|---|

| Spectral Range | 7.7~9.5μm (LW) | Size | 142x58.5x71mm |

| Highlight | LWIR Cooled Camera Modules,T2SL Cooled Camera Modules,640x512 LWIR Camera Core |

||

640x512 15μM Cooled Camera Modules RS058 T2SL LWIR Camera Core

EYAS series cooled AD modules have the pre-amplifier function to convert the analog signal from cooled IR detectors into a digital video stream output. It is available with different resolution formats and different wave bands. EYAS615L is a member of EYAS family with 640x512 / 15μm LWIR cooled detector and RS058 cryocooler integrated.

With EYAS series cooled AD module, it is easy for OEM customers to carry out fast acceptance test on SensorMicro infrared detectors, start rapid secondary development and shorten their development period of modules and complete products based on cooled infrared detectors

We are a leading infrared detector supplier and OEM camera module manufacturer. The company covers an area of 30 thousand square meters with 20 thousand square meters clean room, which can provide customers with a stable supply of infrared products.

- Easy to Develop & Integrate

- Cameralink Interface Output 16bit Raw Data, Serial Port Control

- Integrated Structure, Dimensions are Consistent with Detector

- 5V Single-supply

- Capable of Capturing High Speed Moving Target

| Model | EYAS615L |

| IR Detector Performance | |

| Resolution | 640x512 |

| Pixel Pitch | 15μm |

| Cryocooler | RS058 |

| Spectral Range | 7.7μm~9.5μm LW |

| Cooling Time (25°C) | ≤5.5min |

| Optimal NETD (20°C) | ≤25mK |

| Working Mode | |

| Frame Rate | 1~160Hz Adjustable |

| Working Mode | Snapshot; ITR & Interlace Binning Integration Mode; Windows Mode; Anti-blooming |

| Electrical Specification | |

| Standard External Interface | QSH 60pin |

| Digital Video | Cameralink: Output 16bit Raw Data |

| External Sync | CC1: INT/Frame External Sync; CC2: MC External Sync |

| Communication | Cameralink Serial Port: TFG+/-, TC+/-; 9600bps |

| Power Supply | 1 Channel Imaging Panel: 5V 1 Channel Cryocooler: 24V |

| Stable Power Consumption | 9W |

| Dimension (mm) | 148×58.5×71 |

| Weight | ≤680g |

| Working Temperature | -40°C ~ +60°C |

| Vibration Magnitude | Vibration: GJB Vehicle-mounted High Speed Transport Shock: Half-sine Wave, 40g 11 ms, 3 Axis 6 Direction 3 Times Each |

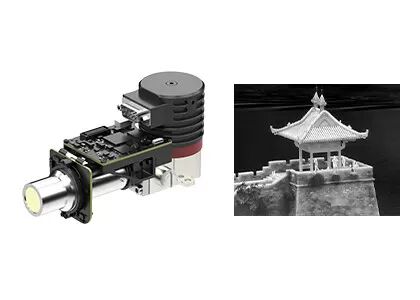

The EYAS615L thermal imaging module is widely used many areas such as Remote Monitoring System, Flight Vision Enhancement System, Multi-sensor Payload etc.

![]()

SensorMicro was founded with a simple but powerful belief: Innovation should serve real-world needs.

SensorMicro exists to empower people and systems to see beyond the surface—into the patterns, the problems, and the possibilities that lie beneath.

By turning invisible heat into visible truth, we help industries make smarter decisions, protect what matters most, and navigate complexity with clarity.

Heeding to our insistence on being self-made and customer-first has become a sure recipe for SensorMicro's momentum. As our business spans much of the globe, we've charged ahead on all fronts—from security, firefighting, industrial inspection, medical care, and machine vision, to environmental monitoring and key aspects of carbon neutrality—helping partners unlock the full potential of intelligent infrared sensing, and connecting the dots of life.

We are more than an infrared technology company. We are a community of people committed to building a sustainable, ethical, and human-centered future. Every pixel of innovation we create is a promise — a promise to protect, to empower, and to serve.

1. What is a cryocooler used for?

Cryocoolers are machines that keep sensors extremely cold so that thermal images can be taken on long-term missions. In many high-end applications, the sensors that capture images require extremely low temperatures.

2. What are the main factors to measure the quality of Cryocooler?

Long battery life and reliable operation are main factors to measure the quality of a cryocooler. SensorMicro cryocooler has a wide operating temperature range and excellent reliability. Its MTTF (Mean Time to Failures) has reached to 10,000 hours, which meets 24*7 boot operation requirements.

3. What is MTTF?

MTTF (Mean Time to Failure) measures a part’s reliability. It shows you how long on average a part lasts before it breaks and you have to replace it. On a basic level, it tells you about the quality of the parts you’re buying. The longer they last, the more value you’re getting from them.